UN/DOT 38.3 Lithium Battery Testing

Since 1984, the United Nations has been issuing recommendations and creating a standard on the transport of dangerous goods. The "Manual of Tests and Criteria" (ST/SG/AC.10/11/) has been regularly updated and amended, and in the early 2000s, a section covering the transportation of lithium metal and lithium-ion batteries (UN 38.3 or T1-T8) was included.

Rev. 7, 2019 incorporated an increased level of clarification and standardization with regards to pre-transport testing. While Rev. 6 allowed for the statement "The UN 38.3 test was passed successfully," since January 1, 2020, every shipper must submit a documented summary which includes the following information:

- Name of cell, battery, or product manufacturer, as applicable;

- Cell, battery, or product manufacturer’s contact information to include address, phone number, email address and website for more information;

- Name of the test laboratory to include address, phone number, email address and website for more information;

- A unique test report identification number;

- Date of test report;

- Description of cell or battery to include at a minimum:

- Lithium ion or lithium metal cell or battery;

- Mass of cell or battery;

- Watt-hour rating, or lithium content;

- Physical description of the cell/battery; and

- Cell or battery model number or, alternatively, if the test summary is established for a product containing a cell or battery, the product model number.

- List of tests conducted and results (i.e., pass/fail);

- Reference to assembled battery testing requirements, if applicable (i.e. 38.3.3 (f) and 38.3.3 (g));

- Reference to the revised edition of the Manual of Tests and Criteria used and to amendments thereto, if any; and

- Signature with name and title of signatory as an indication of the validity of information provided.

In addition to safety during transportation, manufacturers must cover safety at the final point of application (IT equipment, consumer electronics, tools, electric vehicles, etc.) by demonstrating compliance with national regulations, industrial requirements or international standards.

Within the last couple of years, IEC 62133-2 became a de facto standard to demonstrate international compliance within the end product. Variations were adopted by multiple countries including the European Union (EN 62133), United States of America (UL 62133), and Canada (CAN/CSA E62133).

Battery testing as per IEC 62133-2 is very similar to UN 38.3 but it also includes thermal abuse, free fall, overcharging, and continuous low-rate charging. France, Japan, Korea and Switzerland also require forced internal-short circuit testing for cells.

Testing that is required to demonstrate compliance with UN 38.3 includes:

Test T.1: Altitude Simulation

Cells and batteries under test shall be stored at a pressure of 11.6 kPa for at least 6 hours.

Test T.2: Thermal Test

Cells and batteries under test should be stored for at least six hours at 72 ± 2°C, six hours at - 40 ± 2°C with a 30-min transition time between high and low extremes. This cycle should be repeated 10 times. After this, cells and batteries under test should be stored for 24 hours at ambient temperature (20 ± 5°C). For large cells and batteries, duration of the exposure at each extreme should be 12 hours or more.

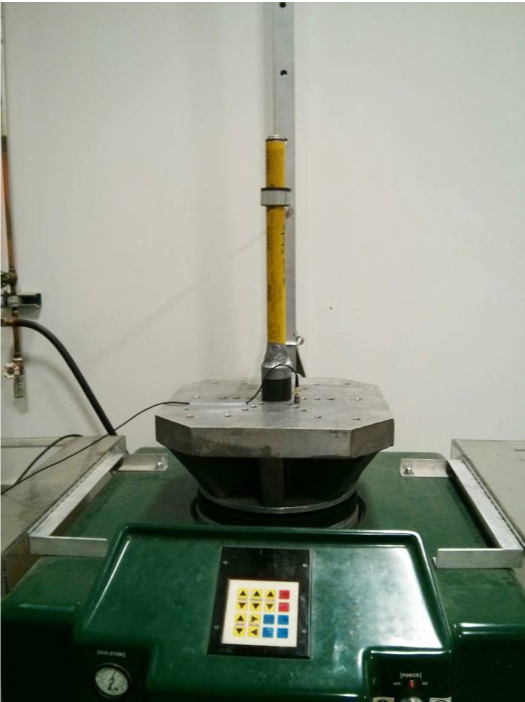

Test T.3: Vibration

Cells and batteries under test should be subject to sinusoidal vibration profile that is specified in UN 38.3 (overall duration is 3 hours per axis)

Test T.4: Shock

Cells and batteries under test should be subject to mechanical shock as per IEC 60068-2-27. Peak acceleration and pulse duration depend on the weight of the cell or battery:

Test T.5: External Short Circuit

Cells and batteries under test should be stabilized at 57 ± 4°C (measured on the external case) and subjected to one short circuit condition (resistance of less than 0.1 ohm). Duration of the short circuit condition is based on the size of the battery and described in UN 38.3.

Test T.6: Impact/Crush

This test is applicable to cells only and (depending on the size of the cell) either Impact or Crush procedure must be used:

- for cylindrical cells 18.0 mm in diameter or more, impact test is applicable,

- for prismatic, pouch, coin/button cells and cylindrical cells less than 18.0 mm in diameter crush test is applicable.

In both cases, purpose of the test is to mechanically abuse the battery and (as a result) create an internal short circuit.

Test T.7: Overcharge

This test is applicable to rechargeable batteries or single cell rechargeable batteries and checks their ability to withstand overcharge conditions.

Charging voltage should be:

- twice the nominal charging voltage or 22 V (whichever is smaller) for batteries with nominal charging voltage less then 18 V,

- 1.2 times the nominal charging voltage for batteries with nominal charging voltage more then 18 V.

In both cases, charging current shall be twice the manufacturer's recommended maximum continuous charging current.

Test T.8: Forced Discharge

This test is applicable to primary or rechargeable cells and checks their ability to withstand a forced discharge by maximum nominal discharge current.

Electronics Test Centre is experienced in cell/battery testing and would be happy to assist you in demonstrating compliance with UN 38.3 or other international standards.